Here is a 2000-word blog post in HTML format on the topic of “Eco-Friendly Algae Bio-reactors without Soil”:

Introduction

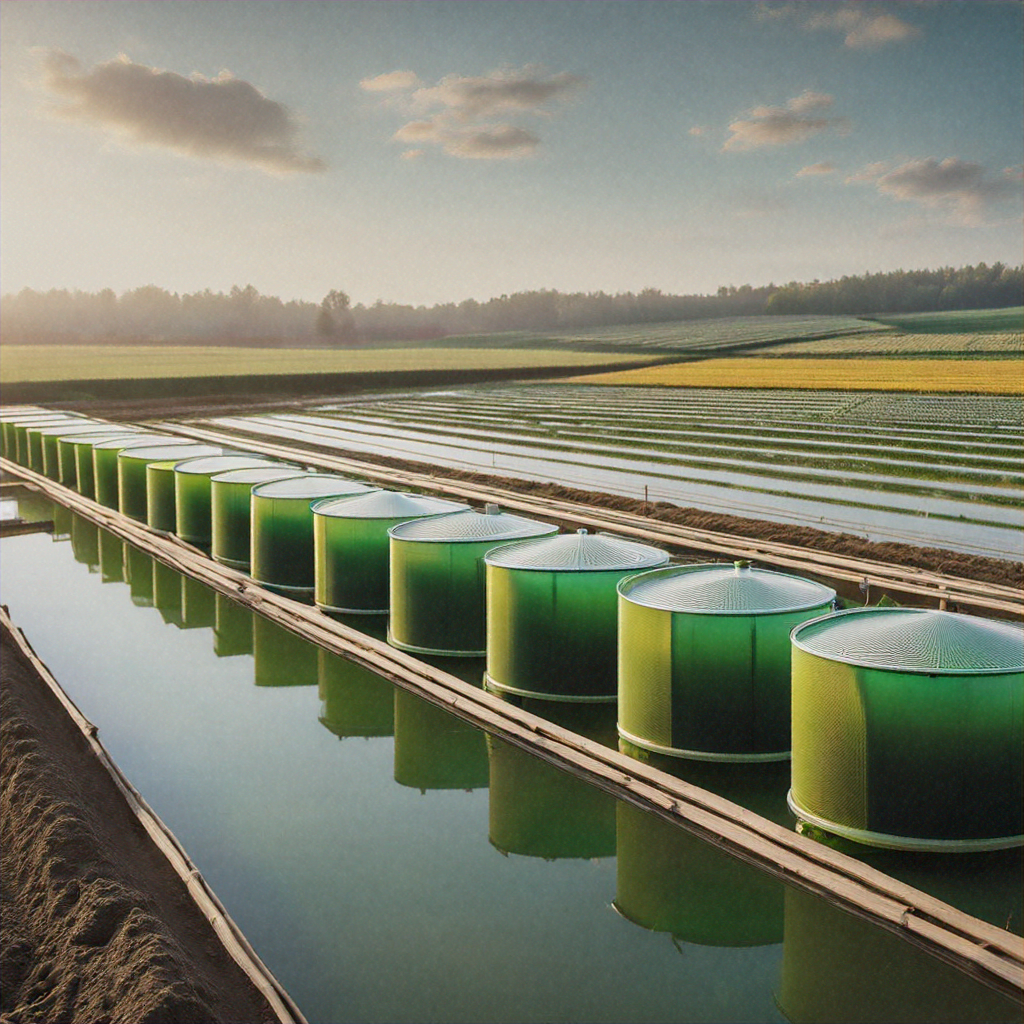

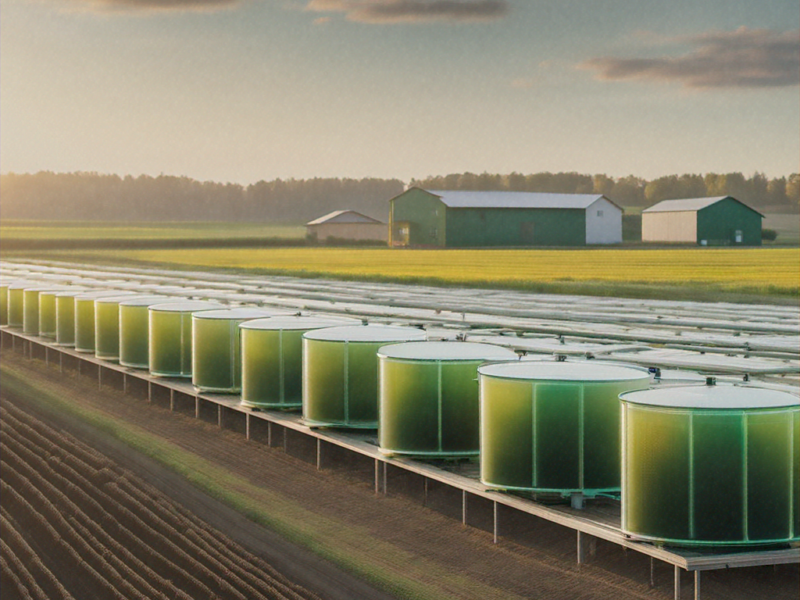

As the global population continues to grow and the effects of climate change intensify, the need for sustainable and eco-friendly food and fuel production methods has never been more critical. One promising solution that has gained significant attention in recent years is the development of algae bio-reactors that operate without soil. These innovative systems harness the power of photosynthetic microorganisms to produce valuable biomass while simultaneously addressing environmental concerns.

Algae bio-reactors without soil represent a paradigm shift in agricultural and biotechnological practices. By cultivating algae in controlled environments, these systems offer numerous advantages over traditional farming methods, including higher productivity, reduced water consumption, and the ability to operate in areas unsuitable for conventional agriculture. This blog post will delve into the intricacies of eco-friendly algae bio-reactors, exploring their design, functionality, applications, and potential impact on various industries.

1. Fundamentals of Algae Bio-reactors

Algae bio-reactors are engineered systems designed to cultivate microalgae under optimized conditions. Unlike traditional agriculture, these bio-reactors do not require soil, instead relying on carefully controlled aqueous environments to support algal growth. The basic components of an algae bio-reactor include:

- A transparent container or vessel to allow light penetration

- A nutrient-rich growth medium

- A mechanism for carbon dioxide introduction

- A mixing or circulation system

- Temperature control apparatus

- Harvesting and processing equipment

The absence of soil in these systems offers several advantages, such as reduced land use, improved control over growth conditions, and the ability to operate in non-arable regions. Additionally, soil-less cultivation eliminates issues associated with soil-borne pathogens and reduces the need for pesticides and herbicides.

2. Design and Engineering Considerations

2.1 Photobioreactor Configurations

The design of algae bio-reactors plays a crucial role in determining their efficiency and productivity. There are several common configurations, each with its own set of advantages and limitations:

- Tubular photobioreactors: Consist of transparent tubes arranged in various patterns to maximize light exposure.

- Flat panel photobioreactors: Utilize thin, rectangular containers with large surface areas for optimal light penetration.

- Column photobioreactors: Vertical cylindrical vessels that can be easily scaled and offer efficient gas exchange.

- Raceway ponds: Open systems that mimic natural pond environments, suitable for large-scale production but with less control over conditions.

The choice of configuration depends on factors such as the desired algal species, production goals, available space, and local climate conditions.

2.2 Light Management

Efficient light utilization is critical for maximizing algal growth and productivity. Engineers must consider several aspects of light management:

- Light intensity: Optimizing the amount of light reaching the algae cells without causing photoinhibition.

- Light distribution: Ensuring uniform light exposure throughout the bio-reactor volume.

- Photoperiod: Controlling the duration and timing of light exposure to mimic natural diurnal cycles or enhance productivity.

- Artificial lighting: Implementing LED or other efficient lighting systems for indoor cultivation or supplemental illumination.

2.3 Nutrient Delivery and Circulation

In the absence of soil, careful management of nutrient delivery is essential. Bio-reactor designs must incorporate systems for:

- Precise nutrient dosing and monitoring

- Efficient mixing to ensure uniform nutrient distribution

- pH control and carbon dioxide introduction

- Removal of metabolic waste products

Advanced bio-reactors may employ automated nutrient delivery systems and real-time monitoring to maintain optimal growth conditions.

3. Algal Species Selection and Optimization

The choice of algal species is a critical factor in the success of soil-less bio-reactor systems. Researchers and engineers must consider various characteristics when selecting algal strains:

- Growth rate and biomass productivity

- Tolerance to environmental stressors (e.g., temperature fluctuations, pH changes)

- Desired product profile (e.g., lipids for biofuel production, proteins for food applications)

- Ease of harvesting and processing

- Resistance to contamination and predation

Common algal species used in bio-reactors include Chlorella, Spirulina, Dunaliella, and Haematococcus. Ongoing research in genetic engineering and strain optimization aims to develop “super algae” with enhanced productivity and resilience.

4. Applications and Products

Eco-friendly algae bio-reactors without soil have a wide range of applications across various industries:

4.1 Biofuel Production

Algae-derived biofuels offer a promising alternative to fossil fuels. The high lipid content of certain algal species can be converted into biodiesel, bioethanol, or other renewable fuels. Advantages of algal biofuels include:

- Higher productivity per unit area compared to terrestrial crops

- Ability to utilize non-arable land and saline water

- Potential for carbon-neutral or carbon-negative fuel production

4.2 Food and Nutraceuticals

Algae bio-reactors can produce high-quality proteins, vitamins, and other nutritional compounds for human and animal consumption. Products include:

- Algal protein powders and supplements

- Omega-3 fatty acids (DHA and EPA)

- Natural pigments and antioxidants (e.g., astaxanthin, beta-carotene)

- Micronutrient-rich food additives

4.3 Pharmaceutical and Cosmetic Ingredients

Certain algal species produce valuable compounds for the pharmaceutical and cosmetic industries, including:

- Anti-inflammatory and anti-cancer agents

- Skin-care ingredients (e.g., moisturizers, UV protectants)

- Natural colorants and preservatives

4.4 Environmental Applications

Algae bio-reactors can be employed in various environmental remediation and sustainability efforts:

- Wastewater treatment and nutrient recovery

- Carbon dioxide sequestration from industrial emissions

- Bioremediation of contaminated water bodies

5. Sustainability and Environmental Impact

The eco-friendly nature of soil-less algae bio-reactors is evident in several aspects of their operation:

5.1 Water Conservation

Compared to traditional agriculture, algae cultivation in closed bio-reactors requires significantly less water. Efficient water recycling systems and the ability to use non-potable water sources further enhance water conservation efforts.

5.2 Land Use Efficiency

By eliminating the need for arable land, algae bio-reactors can be established in marginal or urban areas, reducing pressure on existing agricultural lands and potentially aiding in the preservation of natural habitats.

5.3 Carbon Sequestration

Algae are highly efficient at capturing and utilizing carbon dioxide. Bio-reactors can be strategically located near industrial facilities to directly capture and convert CO2 emissions into valuable biomass.

5.4 Reduced Chemical Inputs

The controlled environment of bio-reactors minimizes the need for pesticides, herbicides, and other potentially harmful agricultural chemicals.

6. Challenges and Future Developments

Despite their potential, algae bio-reactors without soil face several challenges that must be addressed for widespread adoption:

6.1 Scale-up and Cost Reduction

Current algae production systems often struggle with economic viability at large scales. Future developments must focus on:

- Improving bio-reactor design for easier scale-up

- Enhancing automation and process control to reduce labor costs

- Developing more efficient harvesting and processing technologies

6.2 Energy Efficiency

The energy requirements for mixing, temperature control, and artificial lighting can be significant. Research into energy-efficient designs and renewable energy integration is ongoing.

6.3 Contamination Control

Maintaining monocultures in open systems can be challenging. Advances in closed bio-reactor designs and biological control methods are needed to minimize contamination risks.

6.4 Regulatory Framework

As algae-based products enter new markets, appropriate regulatory frameworks must be developed to ensure safety and quality standards.

Future Outlook

The future of eco-friendly algae bio-reactors without soil is promising, with several exciting developments on the horizon:

- Integration with vertical farming and urban agriculture initiatives

- Development of multi-functional bio-reactors that simultaneously produce multiple high-value products

- Advancements in synthetic biology to create algal strains with enhanced productivity and novel capabilities

- Incorporation of artificial intelligence and machine learning for optimized bio-reactor management

- Expansion into new applications, such as space agriculture and life support systems

As technology advances and production costs decrease, we can expect to see wider adoption of algae bio-reactors across various industries, contributing to a more sustainable and resilient global economy.

Conclusion

Eco-friendly algae bio-reactors without soil represent a revolutionary approach to sustainable production of food, fuel, and high-value compounds. By harnessing the power of photosynthetic microorganisms in controlled environments, these systems offer numerous advantages over traditional agricultural methods, including higher productivity, reduced resource consumption, and the ability to operate in diverse locations.

As we face the challenges of climate change, population growth, and resource scarcity, the continued development and optimization of algae bio-reactors will play a crucial role in building a more sustainable future. From producing renewable biofuels to providing nutritious food supplements and environmental remediation solutions, the potential applications of these innovative systems are vast and varied.

While challenges remain in scaling up production and reducing costs, ongoing research and technological advancements promise to overcome these hurdles. As we move forward, the integration of algae bio-reactors into our industrial and agricultural landscapes will undoubtedly contribute to a greener, more resilient global economy.

👥 Readers added context they thought people might want to know

Agri-X VerifiedCurrent formatting suggests planting in June. However, 2025 IMD data confirms delayed monsoon. Correct action: Wait until July 15th for this specific variety.

Have a correction? Log in to contribute.